Energy generation

Renewables

Wind turbine modeling by means of reduced order models:

We work in the development of a coupled aeroelastic model that allows to simulate the temporal behavior of wind turbine blades. Our model requires low computational effort because the blades are modeled as one dimensional solids and as a fluid dynamic counterpart we use the DRD-BEM model which is based on the blade element momentum theory and results in an algebraic problem. This makes it particularly suitable to be coupled with other models that need to simulate the wind turbines with low computational cost.

Applications:

- Aeroelastic study in blades and wind turbines.

- Multicomponent dynamic study of wind turbines.

- Simulation of the interaction between wind turbines and the environment.

- Development of high performance computing tools applied to the resulting models.

Interaction between lower layer atmospheric flow and large wind turbines:

The interaction between wind turbines and their surroundings is a typical spatial and temporal multiscale problem with phenomena sizes ranging from the synoptic scale which modulates the problem through the local scale with sizes of the topographic features to the scale of turbine components.

In this context it is necessary to:

- Develop tools for the numerical modeling that improve the insertion of wind energy into the electrical market and the structural analysis of wind turbines.

- Study the effect of the wind turbines in the atmospheric circulation and viceversa, analyzing how the wind farms could affect weather and climate at local scale and, also, how the global circulation affects the structural design of wind turbines.

Main objectives:

I) Study local circulation characteristics.

II) Evaluate the quality of forecast based on the WRF model.

III) Study of combined (stochastic-dynamic) forecast strategies for short term forecasting.

IV) Multiscale (spatial and temporal) modeling of atmospheric circulation in the presence of wind turbines, with the aim to represent interaction between individual turbines, wind farms and the environment.

V) Study of the power generation variability and the wind turbine structural loads given by the change in meteorological conditions and the interaction with other turbines and wind farms.

External colaborators: Dra. Celeste Saulo (SMN / CIMA-CONICET)

Complex flow modeling by means of the vorticity--velocity formulation of Navier--Stokes equations:

The general objective is the implementation of flow models based on the hybrid, vorticity--velocity, formulation of Navier--Stokes equations to simulate multiphysics flow problems.

One particular objective is to establish a methodology to simulate fluid--structure interaction phenomena that appears when a solid is immersed ins a flowing fluid. This situation is typical in several engineering problems where a fluid exert hydro or aerodynamical forces on a solid which due to deformation modifies the flow field giving raise to a interaction that can positively feedback up to catastrophic failure.

Other objective is the thermomechanical simulation of multiphase flows. In this case, the, possibly, complex reological characteristics of different materials and their dependence on temperature and other variables represent an interesting modeling challenge.

Applications:

Fluid--structure problems in rotor blades which must include the effect of rotation is one of the technological problems envisaged for this methodology.

Another interesting problem from the multiphase flow modeling point of view is the study of the dynamic deformation of geological layers at medium to large scale.

Nuclear Fusion

Plasma physics simulation using the EUTERPE code: EUTERPE is a tri-dimensional girokinetic code used to simulate the behavior of magnetically confined plasmas in Tokamak or Stellerator fusion reactors.

The code belongs to the group of Ralf Kleiber, the Max-Planck Institut fur PLASMAPHYSIK. EURATOM-Association (Germany) and was loaned by signing a document of respect for intellectual property to CSC.

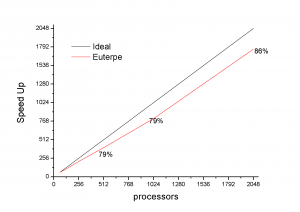

The code was installed and tested in TUPAC, in a basic example of plasma confined to a Tokamak type reactor. Figure 1 shows the Speed up of the code within a node in TUPAC while Figure 2 shows the Speed up obtained in 2048 processors.

EUTERPE Speed up into 2048 processors of TUPAC

Nuclear Fission

Fuel Behavior: The DIONISIO 2.0 code has been developed to simulate most of the main phenomena that take place within a fuel rod during the normal operation of a nuclear reactor. It was designed by the Sector Codes and Models of the nuclear fuel management in CNEA. The code, which has more than forty interconnected models and a modular structure, predict: temperature distribution, thermal expansion, elastic and plastic strain, creep, irradiation growth, pellet-cladding mechanical interaction, fission gas release, swelling and densification. Axial symmetry

is assumed and cylindrical finite elements are used to discretize the domain. At this moment a three dimensional version of the code is under development.

The rod is divided into a user defined number of axial segments where a complete axi-symmetric local domain is solved. All the general rod parameters (pressure, fission gas release, free volume of the rod, etc.) are evaluated at the end of every time step averaging the local values obtained. This modification allows taking into account the axial variation of the linear power and, consequently, evaluating the dependence of all the significant rod parameters with that coordinate.

In regard to fuels for research reactors, the code solves a three-dimensional domain for various types of fissile material consisting of the (which may be monolithic or dispersed) and the cladding may be aluminum or Zircaloy plates. DIONISIO has participated in several international projects of inter-comparison of codes for power reactors with very good results. It has been validated against more than 34 full experiments obtained from the database of the IAEA. The version for fuels research was contrasted with controlled experiments give a very good agreement with measured data.

This year has been installed and tested TUPAC. It has been used to simulate the preliminary designs of fuel to be destined to the Argentine Research Reactor RA-10 and to the reactor CAREM.

Results provided by the code for the fuel CAREM. (Three-dimensional version of the code).

FOSSIL